How Do You Know if Old Radio Tubes Are Good?

In a previous article in this serial (Issue 128), I discussed measurements that help determine the quality of electronic components such as capacitors and resistors. However, most audiophiles are quite content with the electronic components chosen by the designers of their equipment and accept no wish to make changes. That said, ane detail electronic component always requires attention, and that is the vacuum tube. Of course, non all audiophiles wish to use vacuum tube audio equipment, but for those who practice, the quality and the wellness of those tubes play an important role in the sound quality of their systems. The quality of the tubes tin be determined past testing them.

People ofttimes have preconceived ideas about tubes. Tube amplifiers have a reputation for sounding "soft" or "colored," and to have poor frequency extension and flabby-sounding bass. Many of the states have in fact experienced tube amplifiers that confirm these biases, but these qualities are not due to the inherent shortcomings of tubes per se, but to poor design and/or poor-quality components.

For those unfamiliar with how vacuum tubes used for betoken distension work, or need a quick refresher: a heated element (normally a cathode) releases negatively-charged electrons, which are attracted to the positively-charged anode or plate. A filigree, located between the cathode and the anode, and usually kept at a negative voltage relative to the cathode, has the musical signal applied to it, which alters the flow of electrons in accord with the musical indicate (similar a valve controlling the flow of water, hence the Brits call vacuum tubes electron valves). This betoken current induces a voltage at the plate, and the magnitude of the voltage is dependent on the plate resistance. Equally the plate voltage is normally larger than the indicate voltage practical to the grid, so the tube acts every bit an amplifier. (A diode, or rectifier tube used in power supplies, operates differently.)

Tube circuit topology tin be divided into the cocky-bias (cathode bias) or the stock-still bias blazon. Self-bias amps rely on a cathode resistor to enhance the cathode voltage. The grid of the tube is kept at ground potential, thus ensuring a negative grid-to-cathode potential difference (5gk). The plate current decreases when Vgk becomes more negative (the more than negatively charged grid repels more than of the electrons released from the cathode), and increases when Vgk becomes less negative, until the potential difference approaches zero and the filigree starts to conduct current. At this point, the input impedance of the tube rapidly drops, causing distortion unless the driver phase is designed to supply electric current to the grid (a and so-called Class A2 configuration). When the plate current increases, the current going through the cathode resistor also increases, thus raising the cathode voltage. This causes Vgk to go more negative, which in turn reduces the plate electric current. This is a negative feedback mechanism that ensures the plate current stays fairly constant.

While this negative feedback is useful in the steady state, information technology also reduces the amplification of the signal (and then-called degeneration). Therefore, a featherbed capacitor is unremarkably added in parallel to the cathode resistor to avoid incurring negative feedback of the point. The combination of the resistor and the capacitor forms a high-pass filter, which ways the value of the capacitor needs to exist sufficiently large to prevent rolloff of the bass frequencies. The quality of these components have an important influence on the audio quality, since they are in the point path. However, the capacitance normally needed is so big that electrolytic capacitors are frequently used. The equivalent series resistance (ESR) and dielectric absorption (DA) of such capacitors are orders of magnitude higher than moving picture capacitors, making them poor choices for use in signal circuits. This is 1 of the reasons why this type of design could compromise performance.

To get effectually the bug of cathode bias, one can use stock-still bias. In this case, the cathode of the tube is connected to ground, and the grid is kept at a stock-still negative potential. This means a negative voltage power supply is needed, which increases the cost. This blazon of power supply also needs to exist well-regulated, since information technology has a big influence on the sound quality. All the same, this type of design tends to have a cleaner sound and better transient response than cathode biasing.

So what does all this have to do with tube testing? It is because the circuit design determines how much influence sure electrical properties of the tubes have on sound quality. That is why some tubes might sound fine when plugged into a particular amplifier, simply sound horrible when used in a different amp. What are the reasons for testing vacuum tubes? First, nosotros want to make sure the tubes are performing at or shut to their original specifications. Second, nosotros want to match certain characteristics of the tubes so that they will piece of work well together, and tin can determine how they'll behave in various circuits.

Vacuum tubes are handmade products. In the sometime days, after the tubes were assembled by skilled technicians, they were burned in (usually for at to the lowest degree 48 hours) and and then tested, and those that were not upwardly to specification were rejected. The more expensive premium tubes usually had more than stringent requirements during the quality control process. For example, premium tubes such as the E188CC/7308 and 6072a are especially selected low-racket examples of the E88CC/6922 and 12AY7 respectively. Some difficult-to-industry tubes such as certain tubes with a frame grid construction had very high rejection rates. Keep in mind that tubes were the mainstay in electronic equipment up to the late 1960s, and were used in many mission-disquisitional applications. The reputable companies such as Telefunken, AEG, Siemens, Valvo, Western Electric, STC, Mullard, Brimar, Amperex, General Electric, Marconi-Osram, Philips, RCA, Sylvania, Tung-Sol and others produced millions of tubes per year and had very strict quality control.

The Western Electrical 437A frame grid tube, for example, was used in undersea repeaters for telephone lines crossing the Atlantic and Pacific oceans. These tubes can easily final 20 years with continuous use. Imagine having to change out faulty tubes nether these circumstances; just charter a submarine and off y'all go! This tube has extremely high transconductance; in fact, it is possible to build a ability amplifier with simply one 437A per aqueduct. I have a stash of these waiting for projects after I retire…

Nowadays, vacuum tubes are produced generally for guitar amps, where such strict QC is not needed. Many audiophiles therefore similar to utilize tubes produced in a foretime era. New old stock (NOS) of these ancient tubes is becoming increasingly scarce, and many examples existence sold every bit NOS are probably "pulls," or tubes pulled from erstwhile equipment.

Is it improve to buy NOS tubes or recently manufactured ones? (If yous're a manufacturer, information technology's certainly or almost incommunicable to use anything other than new-production tubes because of quantity requirements.) I bought most of my NOS tubes from now-venerable electronics distributors in the early 1990s, when they still had a stash of these subconscious away in their warehouses, but after eBay came on line, this supply quickly dried upwards. Except for a few currently-reputable dealers specializing in NOS sound tubes, who have the knowledge to tell the existent NOS tubes from those that are not – there are counterfeits out in that location – and are honest enough to only sell the genuine articles, I would be very cautious when ownership from other sources. And it is definitely necessary to test the tubes before plugging them into your expensive amplifiers, unless they came from one of the few dealers who test every tube they sell. Even for recently-manufactured tubes, I discover the quality quite variable, and rough handling during shipping tin cause harm to a tube's internal construction. Tubes should be tested afterward purchase, and returned to the seller if faults are discovered.

When using NOS tubes, one needs to pay attention to several aspects. Get-go, these tubes can lose their vacuum over time. The air molecules that have seeped into the tube during the years of storage become ionized when the tube is used for the first time, and these positive ions are attracted to the cathode, striking its surface and causing damage, leading to a shortened lifespan. When these positive ions strike the grid, electrons are released from the grid, and this makes the grid more positively charged. This grid current causes a noise voltage that is amplified past the tube; the higher the resistance of the grid circuit, the higher the noise voltage. The positively charged grid increases the plate electric current, which in plough increases the filigree current and makes the filigree even more than positively charged (so-chosen thermal runaway) until the cathode is depleted. The plate starts to glow red ("ruddy plating") when this happens, which looks very ominous. Cathode-biased circuits, by virtue of their self-correcting nature, are less prone to this problem.

Morgan Jones, the author of the excellent book Valve Amplifiers, recommends baking NOS tubes in an oven at 120oC (248oF) for 12 hours and allowing them to absurd before apply. His experiments showed that the oestrus reactivates the residuum barium nowadays in the tube's getter, the structure inside the tube designed to absorb rest gas and maintain the tube's vacuum.

Tubes with metal-oxide cathodes demand to be handled carefully. If the cathode is made to laissez passer current earlier it reaches an adequate temperature, its life will be shortened. This was unremarkably not a problem in the one-time days when tube rectifiers were used in amplifiers, since the time it takes the rectifiers to warm up and start conducting is acceptable to permit the cathode to reach operating temperature, but modern equipment with solid-country diodes needs to take a time filibuster in the excursion. (Some modern gear, like sure guitar amps, still use tube rectifiers.) Some modern amplifiers take a reputation for eating up NOS tubes, and users should just install current-product tubes in these amps unless circuit modifications accept been made.

What practise we demand to exam to ensure the tubes are working correctly? Open or shorted filaments can be detected using a multimeter, and should be done before plugging the tubes in. Set the multimeter to measure out resistance and connect the meter's exam leads to the filament pins. (Yous tin consult on-line tube manuals for the pin configuration. For testing other parameters, a tube tester is needed.)

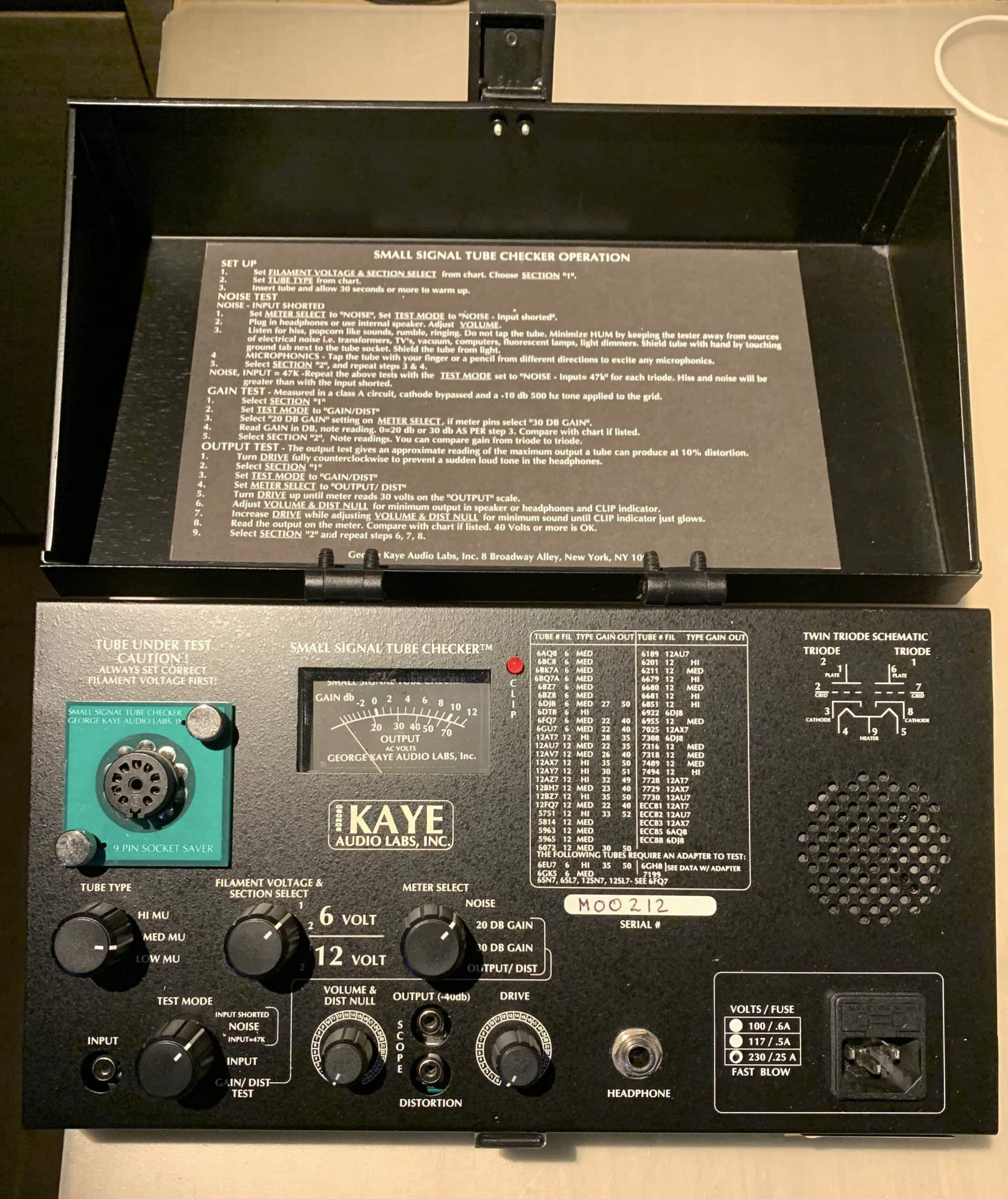

I have a George Kaye Small Betoken Tube Checker that I find very handy for testing smaller tubes for emission, gain, dissonance and microphonics (the trend for a tube to literally human action equally a microphone; you can sometimes hear an audible "clunk" or "ring" when tapping on such a tube when an amp or preamp is on). The tester tests for distortion level when the tube is overdriven; the distortion level rises when the tube'south emission falls, due to aging. The gain is measured at one operating point but, but this is adequate for tube matching in less-critical excursion positions. The dissonance and microphony examination is very useful, as the tester allows y'all to actually listen through headphones as well as come across the noise level on a VU meter. I use this function to sort tubes (from least to most racket) for utilise in the phono stage, the input phase, the commuter phase or the output phase of phono stages, preamps, integrated amps and power amplifiers. Unfortunately, this tester is no longer made, and it can just exam small-signal tubes like 12AX7s, not bigger power tubes. However, I mention its use in order to outline what to wait for when testing tubes, and I'll embrace other vintage and electric current tube testers a bit later.

Adrian's George Kaye Small Signal Tube Checker.

Matching tubes is important if they are to be used in button-pull amplifier output stages, in differential (balanced) circuits, and in outputs that use parallel devices. In all of these cases, the performance of the tubes needs to be matched as closely as possible.

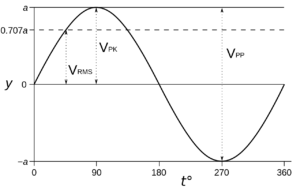

In push-pull output designs, where i tube (or ready of tubes) amplifies the positive phase (or half) of the audio signal and the other tube (or tube set) amplifies the negative phase, an imbalance of the current between the two phases will lead to saturation of the transformer core and a rapid driblet in inductance. If this is immune to persist, the transformer cadre will become permanently magnetized. Many amplifiers allow for adjustment of the plate current of output tubes. If not, or if the amplifier uses cathode bias, matched tubes will be needed. Amplifiers with parallel push-pull output devices frequently do not have separate adjustments for each tube. Therefore, using matched tubes is essential. In differential circuits, mismatched tubes will event in increased distortion, but the event depends on the excursion pattern. Many well-engineered mod amplifiers make use of transistor constant-current sources or sinks to control the plate current of the tubes. This ensures a more stable operation and vastly improves the mutual mode rejection ratio of the differential stage. Such a design is less sensitive to the drift in parameters such equally plate resistance, gain and transconductance.

Graph of a sine wave showing the positive and negative halves of the waveform. Courtesy of Wikimedia Commons/AlanM1.

Ideally, tubes should be matched for emission and transconductance (the change in plate current per unit change in grid voltage). Withal, with most tube testers, transconductance is measured only at a single operating bespeak. To friction match tubes at a variety of operating points, a curve tracer is needed.

The most popular tube tester in history was the TV-vii Series, which was made for the US military past Hickok and others. At one fourth dimension these testers could be picked up at the second-hand market place for very little money, merely they themselves use tubes and need to be restored and calibrated in social club to perform correctly. Audio clubs with sufficient funds and expertise should invest in a laboratory-grade tube tester for their members' utilise. The all-time vintage examples of these include the British AVO VCM 163 and the High german Neuberger RMP370. My recording partner bought ii AVO163s and used one every bit a parts donor to restore the other. The tester is a dandy piece of British engineering, and a real pleasure to use. Vintage tube testers were also made by B&K, Eico, Knight, Precision Apparatus Company, Sencore, Heathkit and others.

[Copper's J.I. Agnew refurbishes tube testers. He'due south located in Europe. Vintage Tube Electronics is located in the US and repairs and calibrates tube testers. – Ed.]

The near famous tube curve tracer is the Tektronix 570, which is rare and expensive. It displays the testing results on a cathode tube display. However, it only provides upward to 300VDC of plate voltage and 150mA of plate current, so some tubes cannot be tested at their typical operating condition. The Tektronix 575 transistor bend tracer is easier to find – and can exist modified to mensurate tubes. In contempo years, several curve tracers aimed at audio hobbyists have become available. These devices connect to a figurer via a digital interface, and all the data is displayed on the computer screen. These devices tin test for emission, gas leaks, short circuit between electrodes, plate resistance, gain and transconductance, and they can also generate tube curves that brandish plate electric current vs. plate voltage at different filigree voltage steps.

The Amplitrex AT1000 is a self-contained unit of measurement that tin can be used without a figurer to measure diverse tube parameters by means of an LED screen. However, it does have to exist used with a figurer in order to generate curves. The software is rather clunky and still uses an RS232 interface. Another limitation is that it only measures the parameters at one operating point. Too, it simply has a power supply for one grid, and therefore can but mensurate tetrodes and pentodes wired as triodes. It does take a headphone output that allows the user to assess tube racket and microphony.

Amplitrex AT1000 tube tester.

The RoeTest was designed past a German language enthusiast and is a very flexible apparatus. Information technology has three grid power supplies, and can measure out tube parameters at different operating points. Still, the designer tin can only supply the software, the blank printed circuit boards, the transformers and the design files for the construction of the chassis. The user must buy all the electronic components, order the chassis from a chassis store and build the device him or herself. The design is quite complicated, and since information technology involves voltages of upward to 600V, the user must be experienced in edifice and testing tube amplifiers to tackle such a project.

A newcomer to this space is the eTracer. Information technology was designed by a Taiwanese electronics engineer, and can test tubes at up to a maximum plate voltage of 750V at up to 300mA. This means that fifty-fifty loftier-powered triodes can be tested. Information technology tin measure cathode-heater leakage, which is important for cascode, SRPP and other topologies where i tube is stacked on top of another and the cathode of the upper tube is at an elevated voltage. If the heater filament of the upper tube is kept at ground potential, there will be a large potential difference between the heater and the cathode, leading to a leakage current, which causes noise. The proper way to design such a circuit is to have a separate heater power supply for the upper tube, elevated to the same voltage as the cathode. This will add to the cost and complexity, and not all manufacturers do it. Users should therefore choose the tubes with the lowest leakage to serve as the upper tubes in these circuits.

The eTracer tin can besides detect gas leaks by measuring the change in plate current when a resistor is added to the grid circuit. The grid current caused by ionized gas molecules volition raise the filigree voltage when the resistor is in place, which can be detected every bit an increase in plate current. The software is very sophisticated, and parameters (plate current, plate resistance, gain and transconductance) at different operating points are displayed but past placing the mouse cursor on dissimilar areas of the graph. Information technology has a curve-matching facility that helps you find tubes that are the near closely-matched to each other. The eTracer can also calculate distortion with different anode loads, which is helpful if yous are designing a excursion.

The device can be bought as a kit or a fully assembled and tested production. The basic model requires the user to hook upwardly the different pins of the tube socket manually using assistant plugs, which reminds me of an old phone switchboard. There is also an optional computer-controlled wire routing module, merely I don't retrieve this is a necessary expense unless yous plan on testing many dissimilar tube types in one sitting. The fully assembled basic tester costs around $1,200, and I view this as a high-value conquering if you lot employ tube equipment regularly. To put this into perspective, a new pair of reissue Western Electric 300B is quoted every bit $i,499 on the manufacturer's website. Shouldn't you lot at least find out if they are working as advertised?

Postscript: A word about output transformers.

The quality of a tube amplifier's output transformer is extremely important. Since it is expensive to build a high-quality transformer, any attempt to cutting toll there could seriously undermine the amplifier'southward sound. This is especially true for single-concluded amplifiers, since an air gap in the transformer is needed to forbid transformer core saturation, which would cause audible baloney and other bug. However, having an air gap lowers the inductance, which compromises low-frequency response. To increase the inductance requires calculation more windings, which adversely affects the loftier-frequency response. Information technology is therefore a balancing act when designing such transformers. An obvious solution is to use different amplifiers that are optimized for unlike frequency ranges to power the different drivers (woofers, midrange and tweeters) of the loudspeakers, using an active crossover, simply I digress. (This is only 1 of the variables that brand owning and operating vacuum tube equipment so intriguing.)

Source: https://www.psaudio.com/copper/article/to-test-or-not-to-test-part-five-vacuum-tubes/

Post a Comment for "How Do You Know if Old Radio Tubes Are Good?"